Compressed Dry Air Testing

Compressed dry air testing in Malaysia

Compressed dry air testing in Malaysia is a standardised procedure for determining the quality of compressed air produced. The test demonstrates that the compressed air in industrial processes is free of contaminants.

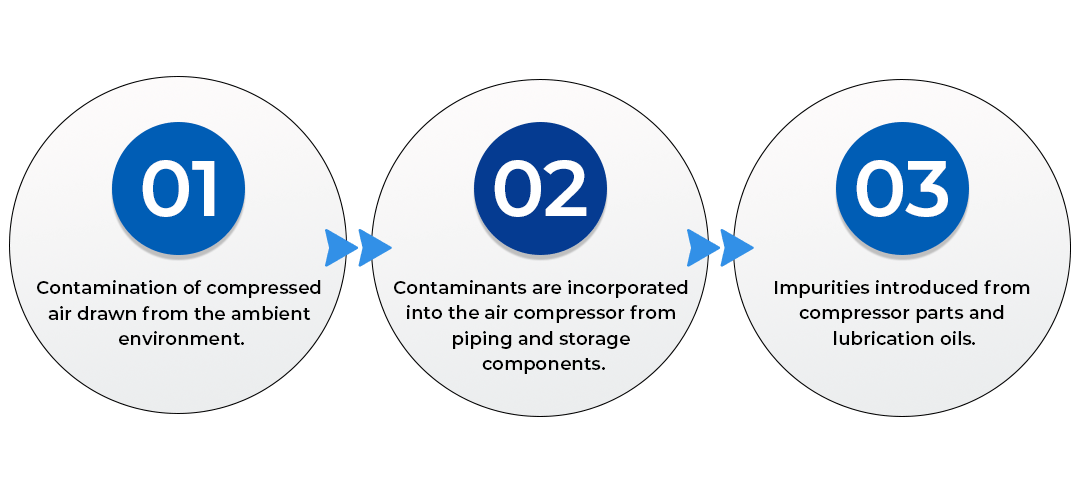

Water, suspended particles, and oil residue are tested frequently from three major sources:

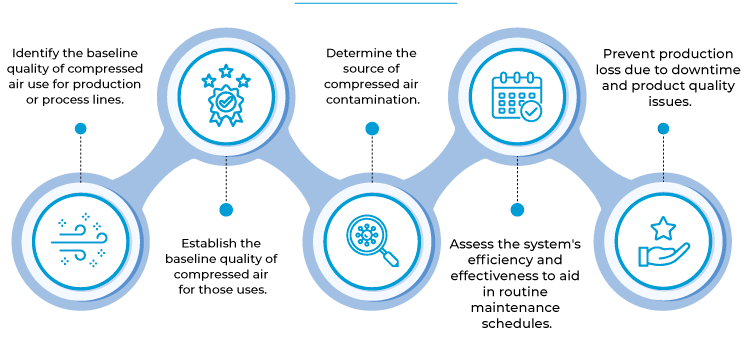

Our objectives for Compressed Dry Air Testing:

Frequently Asked Questions

Compressed air is a critical component in high-quality manufacturing. In sensitive manufacturing processes, proper compressed air testing guidelines must be followed during all process cycles where compressed air is used. Compressed air systems frequently result in the creation of water within air systems.

- Better quality control: A procedure that expedites troubleshooting as the facility’s equipment is tested regularly. Additionally, heavier-duty machine parts have ventilation requirements. There is a greater risk of the air reaching critical parts if the ventilation is inadequate. Thus, the issue could be avoided altogether by promptly addressing it.

- Maintains machinery from breakdown: It safeguards the machinery from failure, which can have major consequences. Malfunctioning manufacturing equipment can result in either minor or major accidents. They may also lead to the deaths of the people who work with them. When a company falls short of expectations or breaks rules, its reputation suffers.

- Compressor performance checks: Compressed testing assures that the compressor is ready and safe for use. When the system fails, it can cause the system to leak or explode. It is very important to be sure a facility has covered all its bases regarding maintaining safety levels and measures on its compressors in any event.