Cleanroom and Performance Testing

Cleanrooms are crucial in ensuring contamination-free manufacturing environments for mission-critical procedures. A responsibly managed cleanroom testing and certification procedure are critical to the correct operation and maintenance of cleanrooms, as well as regulatory compliance.

Cleanroom performance testing is thus critical to a facility’s cleanroom final acceptance, and only once the operating parameters have been verified can the actual “products” be made.

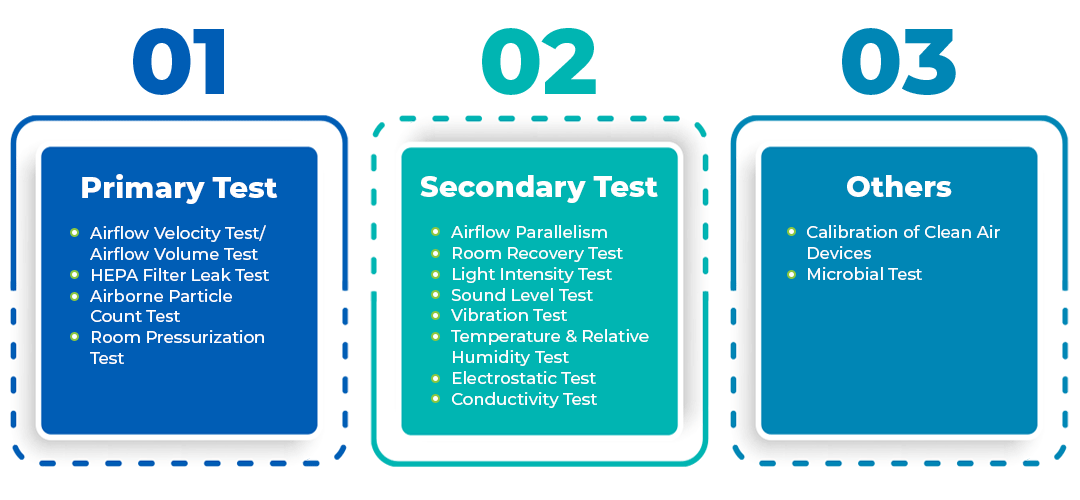

What are the tests that a cleanroom can participate in?

Frequently Asked Questions

The National Environmental Balancing Bureau (NEBB) is a non-profit international organization that certifies businesses and certifies supervisors and personnel in the cleanroom and performance testing.

National Environmental Balancing Bureau (NEBB) is an organisation that is responsible for standard guidelines. It ensures the products being manufactured and produced in the cleanroom facility are appropriately protected within the “clean” environment. This is conducted by a suitably qualified and NEBB-certified independent testing agency.

Cleanroom Performance Testing ensures that the cleanroom was constructed according to specifications, that the running “clean” system is functioning properly, and that the many parameters defined, such as airborne particle counts, air velocity, room pressurisation, temperature, and relative humidity, to mention a few, match the established acceptance

requirements.