Temperature Mapping

Temperature mapping, alternatively referred to as thermal mapping, is a Good Manufacturing Practice (GMP) that enables businesses to monitor and maintain the boundaries of an overall environment. This procedure is used to maintain a constant temperature and humidity level in a regulated region.

What is Temperature Mapping

It is the measurement and documentation of temperature distribution within a room by determining the hottest and coldest locations. The World Health Organisation (WHO) has identified “mapping” as a tool that may be used to locate problem locations that need to be treated, e.g. by changing the distribution of existing air to eliminate hot and cold spots. A temperature mapping study is conducted for a period of time that can range from a few days to a few weeks. It also monitors the room temperature in various locations.

Benefits of Temperature Mapping for your Facility

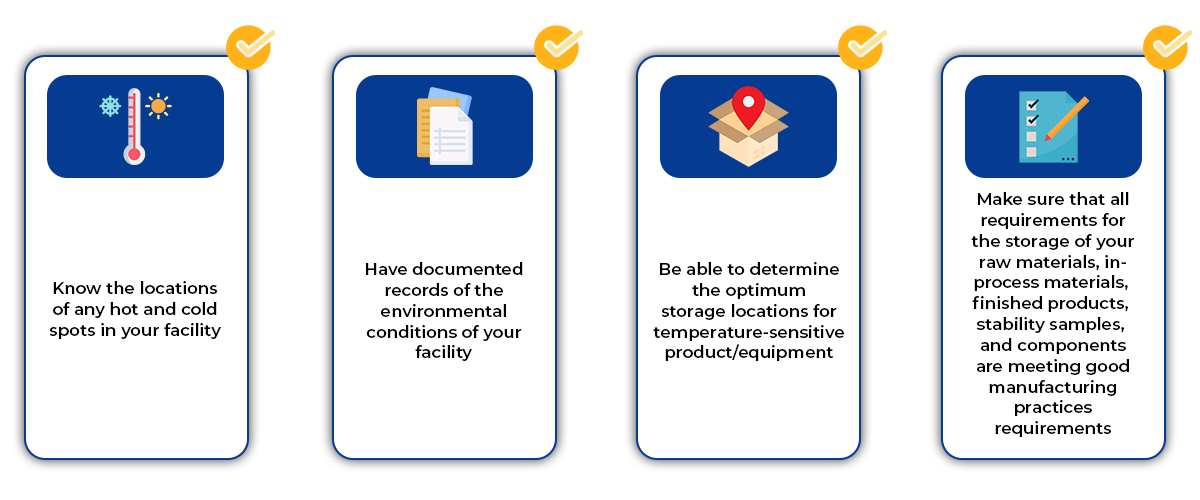

By having IAQ Facility Services finish the temperature mappings of your facility, you will:

How We Do

Data Loggers

Here at IAQ Facility Services, the temperature should be measured over the entire space using data loggers. This is standard for most users. The result is that 9 data loggers will be placed at the top and bottom of the space, each with a sensor in the middle. Additionally, users may also want to check the temperature of the room, totalling 10 points

Let's talk validation!

Talk with one of our experts to induce your questions answered and see how we can facilitate solving your validation services pain points.

Frequently Asked Questions

Temperature mapping is done by deploying data loggers to various locations for minutes to map temperature and humidity distribution. Facilities can identify issues and implement adjustments based on this data. The door openings, electronics, and HVAC systems all cause inconsistent temperature readings.

Temperature monitoring is a common practice implemented following a temperature mapping study. Continuous monitoring is provided in this method with fewer data loggers. Temperature monitoring may also be required by regulating bodies.

Temperatures that affect product quality must be mapped regardless of location. However, sometimes the thermometer readings are only taken from one location on the equipment. This is illustrated in a refrigerator, where things in the back are typically colder than things near the

door. Uneven temperature variations can lead to a product being rendered unusable. Manufacturers must consider the costs and dangers of this practice.

Most users only perform mapping once a year. However, during the hotter or colder months throughout the year, there is a high demand for Temperature Mapping. Building or facility managers alike map the space to better understand how ambient temperatures influence the environment.